Views: 0 Author: Site Editor Publish Time: 2024-04-10 Origin: Site

When it comes to crafting intricate designs and ensuring impeccable accuracy in metal tube fabrication, CNC laser cutting technology stands out. In this blog, we explain the basics of CNC laser cutting, including the advancements of fiber laser pipe cutting machines in metalworking.

CNC tube cutting technology represents a high level of precision engineering in metal fabrication. Utilizing Computer Numerical Control (CNC), these machines offer excellent control and accuracy in cutting metal tubes to exact specifications. By programming intricate designs into the system, manufacturers can achieve complex shapes and precise cuts with remarkable consistency. This level of precision ensures superior quality and maximizes material utilization, minimizing waste and reducing production costs.

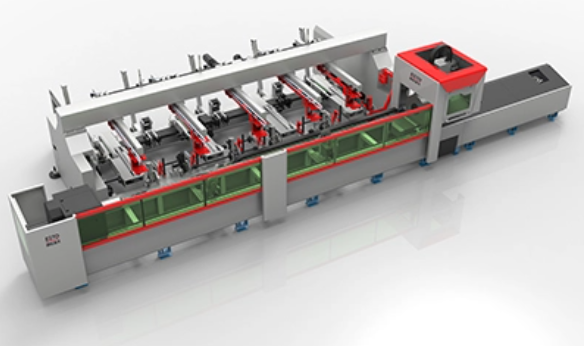

Fiber laser pipe cutting machines represent the pinnacle of tube cutting technology, offering unrivaled speed, accuracy, and reliability. These machines leverage fiber laser technology to deliver precise cuts with minimal distortion.

Metal tube laser cutting machines offer exceptional precision, allowing for the production of intricate designs and complex geometries with micron-level accuracy.

The focused laser beam ensures clean, sharp cuts, minimizing the need for secondary processing and reducing material waste.

These machines are capable of cutting a wide range of materials, including stainless steel, aluminum, and titanium, among others.

They can handle various tube shapes and sizes, from round and square to rectangular and oval, catering to diverse manufacturing needs.

Metal tube laser cutting machines operate at high speeds, significantly reducing production times and increasing throughput.

With rapid acceleration and deceleration rates, these machines maximize efficiency and productivity, enabling manufacturers to meet tight deadlines and production targets.

Unlike traditional cutting methods such as sawing or milling, laser cutting produces minimal heat, resulting in a small heat-affected zone (HAZ) along the cut edge.

This reduces the risk of material distortion, warping, or metallurgical changes, preserving the integrity of the workpiece and ensuring consistent quality.

Metal tube laser cutting is a non-contact process, meaning there is no physical contact between the cutting tool and the workpiece.

This eliminates the risk of tool wear or damage, resulting in a longer machine lifespan and reduced maintenance requirements.

Many metal tube laser cutting machines feature advanced automation capabilities, such as automatic material loading and unloading, as well as integrated CAD/CAM software for seamless design-to-production workflows.

Automation streamlines production processes reduces labor costs, and improves overall workflow efficiency.

Metal tube laser cutting machines are highly scalable, accommodating both small-scale prototyping and large-volume production runs with ease.

Manufacturers can easily customize cutting parameters and tooling setups to meet specific project requirements, offering unparalleled flexibility and adaptability.

The applications of CNC tube cutting technology are virtually limitless, spanning a wide range of industries and sectors. From automotive and aerospace to architecture and construction, CNC tube cutting machines play a pivotal role in shaping the world around us. Whether it's crafting exhaust systems for high-performance vehicles or fabricating structural components for skyscrapers, the precision, and versatility of CNC tube cutting technology enable users to tackle demanding projects with precision.

5-axis tube cutting machines produce complex three-dimensional cuts and intricate shapes with remarkable precision. By moving the cutting head along five different axes of motion, 5-axis laser tube cutting machines can perform bevel cuts, chamfers, miter cuts, and other intricate geometries with unparalleled accuracy and quality.

One of the key advantages of 5-axis tube cutting technology is its enhanced flexibility, which allows for the production of a wide range of complex parts and components that were previously unattainable. This level of precision minimizes errors and ensures tight tolerances, resulting in finished parts that meet the strictest quality standards.

EETO is a leading fiber laser cutting machine manufacturer in China, committed to providing innovative solutions that empower our clients to achieve their manufacturing goals with precision and efficiency. If you're looking for professional fiber laser machines, we invite you to reach out to us today. Send us your project or machine requirements, and let our team of experts customize solutions for you.